CCSN SHOWS :How to design of Diesel Generator Room

With the development of society, there are more and more types and quantities of electrical equipment in construction machinery, self-supplied power stations, and civil buildings. Among these electrical equipment, in order to meet the reliability of these equipment, the city power grid when two independent power sources cannot be provided, the method of using diesel generator sets as a complementary power source in the design is generally adopted.

This time mainly introduces the civil room construction. Although diesel has a high ignition point and relatively low fire hazard, in civil buildings, if the diesel generator set is installed in the main body of the building, it is still dangerous in theory. Considering the ventilation during the operation of the unit issues such as noise, vibration, etc. undoubtedly require us to comprehensively consider and take adequate preventive measures. The specific practices include the following aspects.

1. Selection and arrangement of generator room location:

1.1 Taking into account the air intake, exhaust, and smoke exhaust of the generator room, according to the requirements of the "Civil Building Electrical Design Code", the diesel generator room should be arranged on the first floor, but usually large public buildings, commercial buildings and other civil buildings The first floor is a golden zone, and the first floor will bring a certain amount of noise to the surrounding environment. Therefore, according to the regulations, it can also be arranged in the basement when it is really difficult. Because the basement is not easy to enter and exit, the natural ventilation conditions are poor, which brings to the design of the room. A series of unfavorable factors should be carefully designed. The following points should be paid attention to when selecting the location of the room:

1.1.1 It should not be located in a room with no external walls around, creating conditions for hot air ducts and smoke exhaust ducts to be discharged outside;

1.1.2 Try to avoid the main entrance, facade and other parts of the building, so as not to affect it by exhaust air and smoke;

1.1.3 Pay attention to the impact of noise on the environment;

1.1.4 It should not be located directly under or adjacent to toilets, bathrooms or other places where water often accumulates;

1.1.5 It should be close to the substation of the building, which is convenient for wiring, reduces power loss, and is also convenient for management;

1.1.6 It should not be near a room with anti-microvibration;

1.1.7 There is an oil storage room in the machine room.

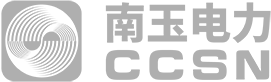

1.2 The layout of the room

1.2.1 The diesel generator room shall be separated from other parts by partition walls with a fire resistance rating of not less than 2.00 hours and a floor slab of 1.50 hours;

1.2.2 The machine room should have two entrances and exits. The size of one exit should meet the requirements of the handling unit. The door should be fireproof and soundproof, and it should be opened outward.

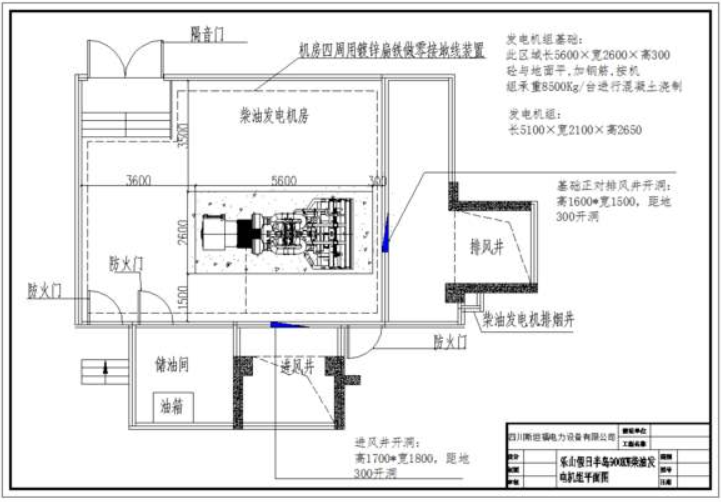

1.2.3 The walls and ceilings around the room are used as sound absorbers to absorb part of the sound energy and reduce the reverberation sound caused by sound wave reflection;

1.2.4 The layout of the equipment in the room should meet the requirements of the "Code for Electrical Design of Civil Buildings", and strive to be compact, safe and easy to operate and maintain.

2. Inlet and exhaust design

The ventilation problem of the diesel generator room is a problem that must be addressed in the design of the engine room, especially if the engine room is located in the basement, it must be handled well, otherwise it will directly affect the operation of the generator set. The exhaust air of the unit should generally be equipped with hot air ducts, which should be organized in an organized manner. It is not advisable to let the diesel engine radiator dissipate heat in the engine room. The hot air duct and the diesel engine radiator should be connected together with a soft joint at the joint. The hot air duct should be straight. To turn, the turning radius should be as large as possible and the interior should be smooth, and the air outlet should be as close as possible and facing the hot air duct of the radiator. When it is difficult to reach out directly outside, it can be set to lead out. Sufficient fresh air should be provided in the machine room. The air intake is generally natural, and the air inlet should be directly opposite to the generator end or on both sides of the generator end. The air inlet and air outlet should be located at both ends of the machine room to avoid short circuit of air flow and affect the heat dissipation effect.

The area of the air outlet and air inlet of the machine room should meet the requirements of the following formula:

S1>1.5S; S2>1.8S

Where:

S-the heat dissipation area of the diesel engine;

S1-the area of the air outlet;

S2-the area of the air inlet;

3. Smoke exhaust system

When a diesel generator set burns, it will not only produce a large amount of hot gas, but also a large amount of combustion exhaust gas. These exhaust gases must be specially treated before they can be discharged into the air from a dedicated exhaust shaft. The treated exhaust gas must be led to a high altitude or a place where it will not interfere with other people through a steel smoke pipe or a professional smoke shaft. When using steel pipes, the thermal expansion and contraction of the pipe must be considered. When the straight section of the pipe is long, the corresponding compensator should be selected; for the place in the machine room and easy to contact with people, the insulation material (thickness 50mm) should be used. When wrapping the smoke pipe, it must be ensured that the insulation material does not affect the free expansion and contraction of the smoke exhaust hose and compensator. In addition to the use of steel smoke pipes to lead the flue gas to the outside, prefabricated professional smoke wells can also be used.

In order to ensure water for dust removal equipment, make-up water for chilled liquid of the unit, and water for washing the ground of the machine room, a mop pool should be set up in the generator room.

4. Daily fuel tank

According to the "Code for Electrical Design of Civil Buildings", fuel tanks should be installed for diesel generators to run for 3-8 hours. Civil building fire protection requirements are more stringent. A dedicated fuel storage room should be set up in the engine room with daily fuel tanks. The total storage capacity should not exceed the required amount for 8 hours, and the volume of the intermediate oil storage tank should not exceed 1 cubic meter according to the building design fire protection code. The volume of the daily fuel tank is calculated as follows:

V=G*C/r/A

V-----Volume of daily fuel tank (m3);

G-----Diesel fuel consumption (kg/h);

r------fuel density (kg/m3), light diesel oil is 810~860;

A------Fuel tank full factor (usually 0.8);

C------Oil supply time (3~8h).

The oil storage room should be separated from the generator by a firewall. When the door must be opened on the firewall, a Class A fire door that can be closed by itself should be installed and opened to the generator room. The lamps in the fuel tank are explosion-proof, and daily ventilation is provided.

5. Basic design

According to the requirements of generator manufacturers, certain vibration reduction measures must be taken for generator sets. In order to reduce vibration, a concrete foundation should be set up according to the size of the diesel unit. The sides of the foundation should be 15~30cm beyond the widest part of the unit. When installing the unit, drill holes in the foundation relative to the fixing bolts on the underframe of the unit, Fix the unit with expansion bolts. Taking this measure, the vibration of the unit is partially absorbed by the concrete. In addition to providing the static load of the unit and the volume of the concrete foundation, the electrical specialty should also consider the dynamic load of the unit. The dynamic load can be obtained from the relevant manufacturer or 1.5 times the static load of the unit.

The reinforced concrete foundation must guarantee a certain maintenance period before the equipment can be put in place. A 10cm wide oil trench should be designed around the foundation to facilitate cleaning of the fuel or lubricating oil dripping from the equipment.

6. There are generally three types of grounding for diesel generator rooms:

Working grounding: the neutral point of the generator is grounded;

Protective grounding: the metal shell of the electrical equipment is grounded normally;

Anti-static grounding: the equipment and pipelines of the fuel system are grounded.

Various grounds share the grounding device with other grounds of the building, that is, a joint grounding method is adopted. When designing, set grounding embedded parts in the machine room.

This article only further elaborates on the issues that should be considered in the design of emergency diesel generator rooms. Other design requirements of emergency diesel generator sets must comply with the requirements of the "Civil Building Electrical Design Code" and the power supply design manual.

References:

1. "Code for Electrical Design of Civil Buildings"

2. "Industrial and Civil Power Distribution Design Manual"

3. "Code for Fire Protection Design of High-rise Civil Buildings"

4. "Code for Fire Protection Design of Buildings"

CCSN Power Inc. All Rights Reserved

Posted by: Liu Ming

Reviewed and translated by: Kailon Chung